One of our students finally saw all of their hard work pay off in the form of a rocking chair (makes me want to keep teaching for a long time). Hard work and attention to detail created a piece of furniture that anybody would be proud to have in their home. This is made of red oak with laser etched arm details and leather seat material. Very proud of your work young Man!

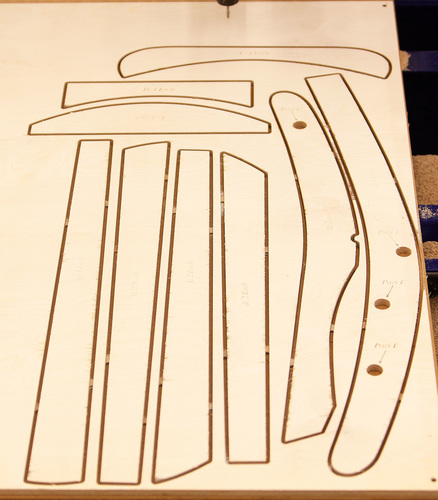

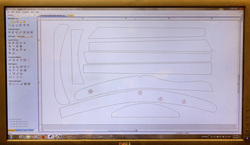

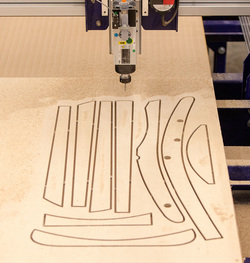

One of the things that we are working is getting the CNC curriculum developed for the program. Thanks to Randy Johnson and the folks at Shopbot, this is an easier task than it would have been. We are using several of the ideas and projects from the Summer course that Randy taught in Washington to get the kids up and running.

The first project that students actually produce on the machine is a series of three custom coasters. This teaches the kids about pocket and v-carve techniques as well as offsets, drawing and resizing shapes and aligning objects to a vector.

This is also an great opportunity for students to get hands on experience with operating the CNC itself. We work on changing bits, moving the gantry (learning x, y and z axes), zeroing the xy and z axes, affixing materials to the spoilboard (we learned a lot from our first failure in regards to this particular point) and simply getting comfortable with a machine that can be a bit intimidating at first. Next up is inlays on the CNC!!!

RSS Feed

RSS Feed