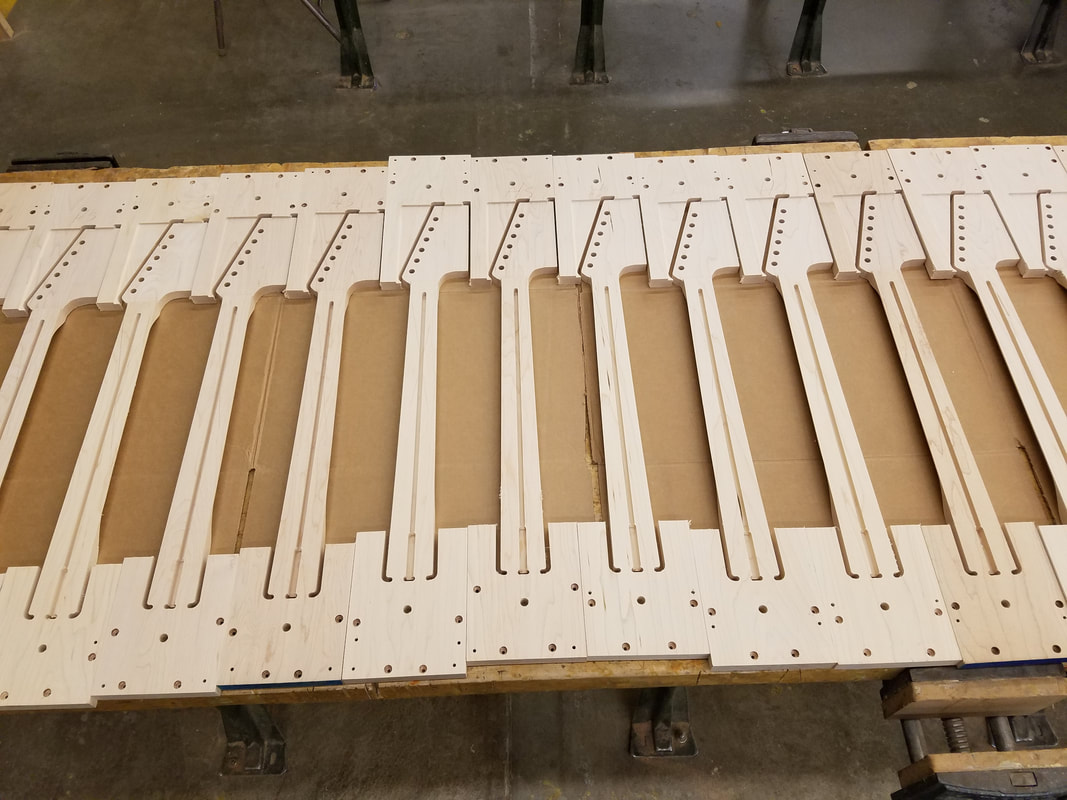

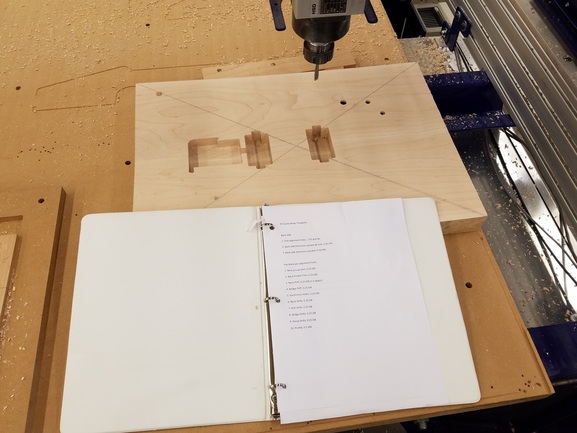

| To the left we have our two luthiers tool kits. Each kit is supposed to be sufficient for 6 to 8 students, but I think that is a bit of a stretch. I am hoping that a grant I applied for will come through with another kit. | The image on the right is the beginnings of the guitar bodies. We are using Alder and Poplar for the bodies, Poplar for those who want to paint and Alder for the other finishes. |

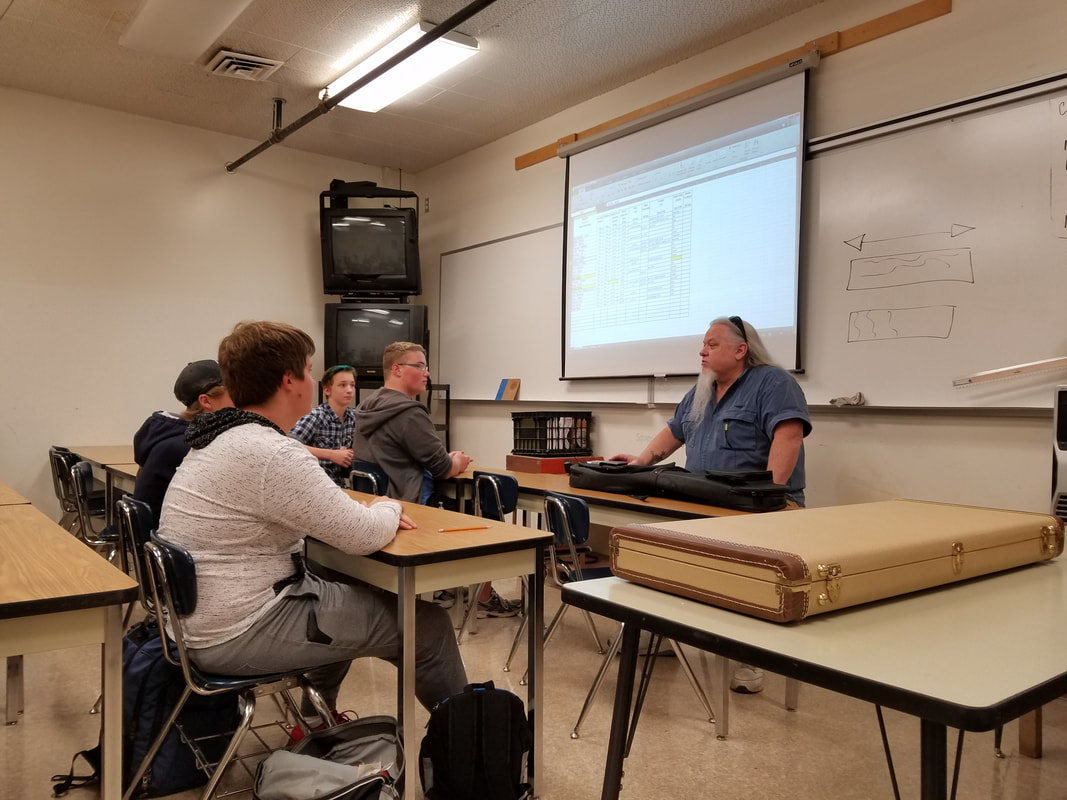

| Once again, our good friend and mentor John Page showed up to meet the students and answer any questions they had. He is going to be coming in to work with the kids on a regular basis which is just a fantastic opportunity for all of us involved. It was one of my students that hooked us up with John. The students Grandfather, Wayne, is a good friend of Johns. Wayne brought in his John Page Custom for us to drool over, it was number 2 or 3 of Johns first custom line nearly ten years ago. A beautiful piece of art and the kids had the opportunity to really take a close look at the instrument. |

| The students have chosen lots of different body styles to work with and we are still machining some of the last ones over the next two days. They take a lot of work but it will all be worth it in the end. I am still amazed each and every day with the creativity of these kids. Their excitement is so contagious when they get their hands on a new part of their instruments. |

RSS Feed

RSS Feed